Nouvelles à la une

-

25/09/2025

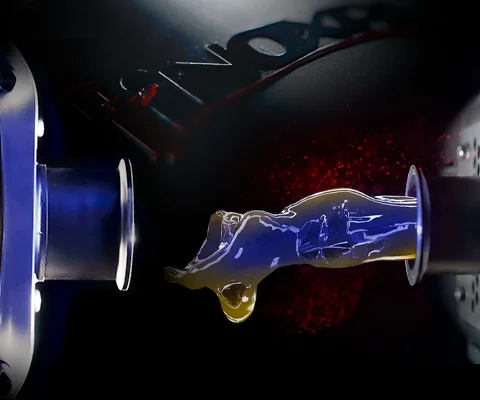

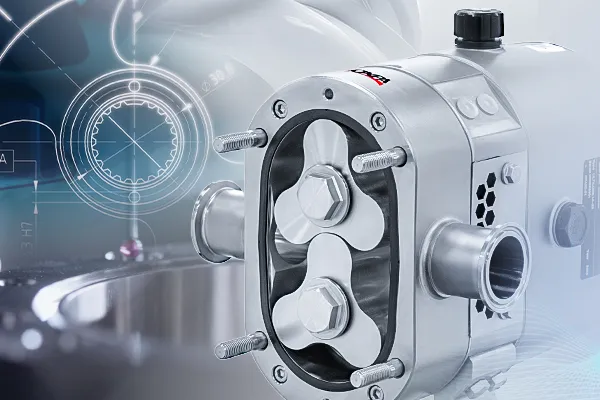

25/09/2025UltiLobe : la pompe à lobes ultime

UltiLobe Découvrez, la dernière innovation d’INOXPA en matière de pompes à déplacement positif, conçue pour les environnements exigeants.

-

30/07/2025

30/07/2025Des solutions globales qui font la différence

Chez INOXPA, nous proposons depuis des années des solutions complètes et personnalisées, prenant en charge l’intégralité du processus d'ingénierie, d’automatisation et d’assemblage.

Produits

Études de cas

Découvrez comment nous avons aidé des petites et grandes entreprises du secteur à atteindre leurs objectifs.

Système NEP pour ligne d’extraction de café

Système de nettoyage NEP automatique à trois cuves et trois lignes d’envoi pour une usine de production d’extraction de café en...

Microbrasserie artisanale durable

Installation d’une microbrasserie semi-automatique pour augmenter la production et améliorer l’efficacité, fonctionnant entièrement...

Prochains salons

-

Applications

Nous avons la solution pour votre procédé

-

Industrie alimentaire

-

Industrie de la boulangerie

-

Industrie laitière

-

Industrie des boissons

-

Industrie cosmétique et pharmaceutique

Nos vidéos les plus récentes

PARTNER PORTAL

Nous avons conçu une solution en ligne qui centralise et simplifie l’ensemble des démarches liées à l’achat de nos produits. Grâce à Partner Portal, vous pouvez passer vos commandes de manière autonome et automatisée, tout en accédant à toutes les informations utiles : historique, statut, délais de livraison et certificats associés.

Services

INOXPA offre à tous ses clients un service d’assistance et de conseil avant, pendant et après l’achat. L’ensemble des services proposés par INOXPA accompagnent les clients de bout en bout, de la sélection du produit qui correspond le mieux à leurs besoins à son utilisation appropriée : planification, installation, formation, résolution de problèmes, maintenance et réparation, mise à jour et modernisation.

-

Mise en service

-

Assistance

-

Améliorations

-

Maintenance

-

Service client

INTERPUMP GROUP

-

Milliards d’euros de chiffre d’affaires

-

Employés

-

Entreprises

-

Pays dans lesquels nous vendons directement nos produits